Table Of Content

Expect additional costs when adding interior walls to an already established home due to the challenges that arise. These include less room to work, and extra care needed to avoid dust and debris since the homeowner is often living in the residence during construction. House framing’s primary purpose is to provide support for the other building materials in your home.

The Building Code: Framing Ground Rules

This seemed like the easiest and most robust solution for a cabin that would potentially have renters and regular use. We were lucky with the land as it was included in the purchase of our main house, which is just up the hill. We began working on design ideas in March 2019 and it was finally finished in January of 2021. There were a few YouTube videos that I loved and would get me excited about finishing the cabin. One was old school legend Dick Proenneke, and this guy is kind of a contemporary legend too. If anything, these two film series just made me realize that I will probably never build my own cabin...

Plan: #177-1005

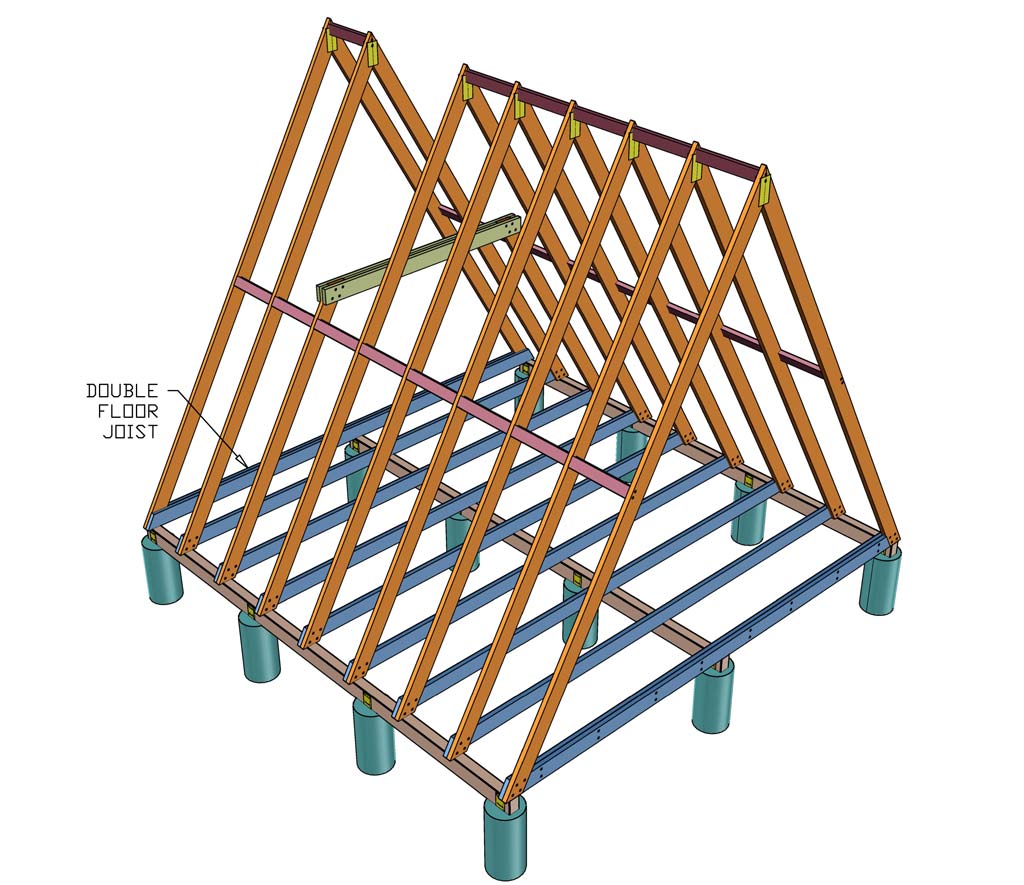

The last truss will need to be rotated and installed facing the front. Also, the distance between the last two trusses will be shorter, so the bridging blocks will be shorter. Then cut and install the double floor joist just like the first truss. The tradeoff is that you get to do what you want without the limitations of premade plans. Not necessarily, the cost of land, building supplies, materials, and even labor might not come cheap, but it is possible to build an A-Frame house without spending too much money if that’s your aim.

Lumber Frame

Framing costs $11 to $30 per square foot on average for labor and materials, depending on the project size, layout, and the choice of wood or steel. Pressure-treated lengths of 2×6 lumber, which form the first layer of the mudsill, are solidly attached to the foundation with bolts that have been embedded in the foundation walls. They provide a bearing surface that prevents contact between the untreated floor joists and the concrete foundation. A second layer of standard lumber is sometimes applied over the pressure-treated boards.

Two Friends Started This Prefab Company Where the Cabins Come on Wheels - Dwell

Two Friends Started This Prefab Company Where the Cabins Come on Wheels.

Posted: Fri, 08 Sep 2023 07:00:00 GMT [source]

To protect the inhabitants of our houses as well as the people who build them, houses are built according to a set of rules called building codes. These codes spell out the minimum requirements for most aspects of building a house. Code stipulates the size and grades of the lumber and fasteners that go into the frame as well as how the frame should be assembled to handle all the forces that affect it. Building according to code is your assurance that the house will be strong and safe.

Framing walls while constructing a new home will be in the lower price range while adding new walls inside an existing home will be in the higher price range. The cost to frame a wall is $1,000 to $5,000 on average, depending on the wall size and the stud spacing. This price includes labor and materials for framing and drywall. The cost to frame an addition is $4,400 to $12,000 on average for 400 square feet, depending on the layout, foundation type, and whether it's on the first or second floor. Framing a second-story addition typically costs more due to the extra work of reframing the roof.

Floor sheathing stabilizes the joists and provides a solid, flat base for wall framing and finish flooring. This home design became popular because of its snow-shedding capability and cozy cabin feel. A typical style for contemporary vacation homes, A-frame plans are more prevalent in spots with a lake-front view and are often spotted near the ocean or tucked away in mountainous regions. Before installing insulation and drywall, think about the interior living space and how it would look. If you plan to install cabinets on the wall, you will need to add additional backing blocks or frames to support them. Or, if you want to hang a large TV or any other heavy object, you will need framing supports.

Since lumber pricing fluctuates, it can be tough to predict costs in advance. Metal framing costs historically tend to run a bit higher than wood by about 10%. Check with your local lumber yard or general contractor for local pricing.

Then the rest of the plywood pieces would follow the same pattern. Before you start covering the roof with plywood, check to see if you need any additional backing or bridging blocks to hold the plywood. You don’t want any plywood sections to be loose or not secured to the frame. Just like the plywood on the floor, all plywood edges should land on the boards. Using the same method as you installed the plywood on the floor, first install the bridging blocks, and then install the plywood.

However, you can estimate four months to eight months depending on the size and complexity of the build. When it comes to doing it right, there’s no better expert to tell you what to do and what not to do than Andrew Szeto. An Ottawa, Ontario-based skater, outdoorsman, and woodworker, Szeto is proof that anyone can build the cabin of their dreams with hard work and good friends. We were impressed by how he was able to build his A-Frame house for only $8,000 USD, so there’s plenty to learn in this list of his best tips and tricks for how to build an A-Frame house below. As mentioned before, thanks to its architectural design, heating and cooling an A-Frame is a naturally energy-efficient process on its own.

Platform framing is easier than balloon framing because you can construct and erect the second story walls on the second story floors. First step is to lay the sole plate for slab construction, or sill plate for a foundation/floor, against the anchor bolts, mark their location and bore the holes. If you are planning on buying, building, or renovating an A-frame house, we’ve gathered a handful of our favorite examples of this style home that will bring you plenty of inspiration. Collar ties are horizontal members that join opposing rafters together. They stiffen the roof and can serve as ceiling joists when the attic is used as living space.

You can use different angles to modify the shape, however (see “Common Floor-to-Rafter Angles,” below). For a small structure like the one described here, three people can lift the assembled triangles into place without the assistance of special equipment. A structure with rafters greater than 24 feet may prove too unwieldy for a crew of amateurs. For a large A-frame, plan a lot of windows to keep the interior from being too dark. Simple designs without dormers and few valleys or hips—the place where two slopes join—will fall on the low end. Complex designs with numerous angle changes and dormers will end up on the higher end of the spectrum.

No comments:

Post a Comment